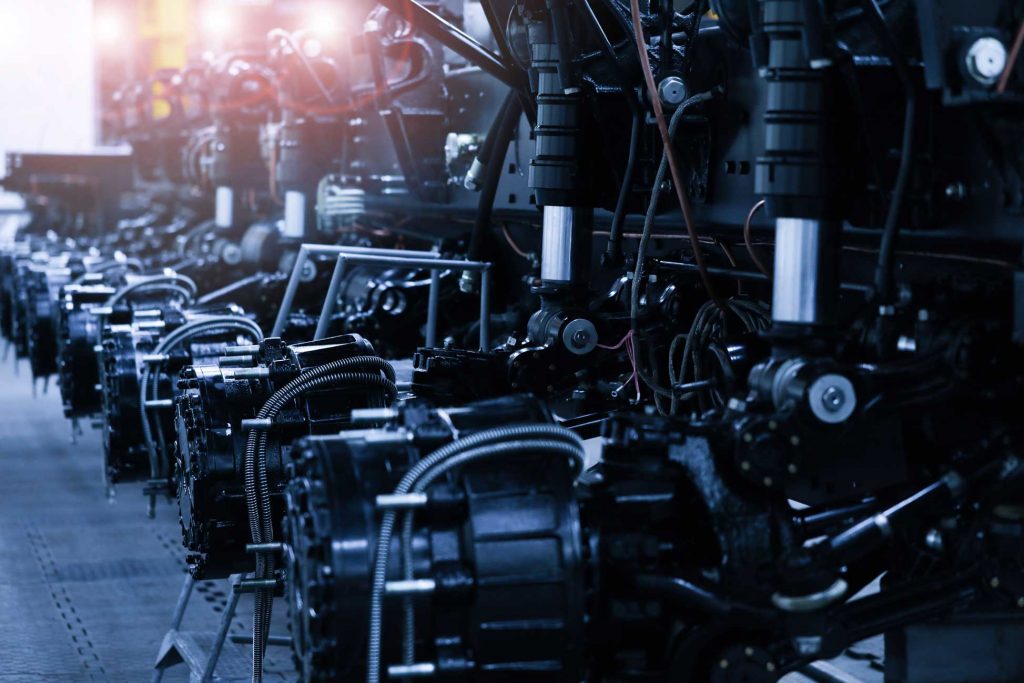

Over 30,000 bolts are tightened every production day at the axle production facility of MAN Truck & Bus AG in Munich. To consistently achieve this output at the highest quality, machines must be kept in top condition at all times through regular maintenance and care. Since our goal is to continuously optimize automation and production, even long-established practices must be re-evaluated. That’s why we no longer rely on air-operated impact wrenches in axle assembly, but predominantly on electronic screwdrivers with integrated monitoring functions. Only with this technology can we ensure the precision of bolted joints and the safety of our vehicles, even under extreme stress.

Production structure in focus

Maintenance is no longer just about repairing defective machines and systems — it’s also about collecting innovative knowledge on optimal production structures. This includes automatically securing critical production data and constantly monitoring equipment. In 2012, we laid the foundation for a new system: screw cycle recording. The basis for networking all screwdrivers was implemented for 80 screwdriving systems. Now it is possible to store production data — such as torque and angle of rotation — on a central server and retrieve it online. In cooperation with the planning department of software company CSP and the electrical maintenance team, the existing IPM archiving system was adapted so that it automatically triggers a maintenance order after every 100,000 to 1 million screwdriving cycles.

Maintenance at the optimal time

Maintenance can now be performed condition-based and at exactly the right time — something that was previously difficult due to fluctuating production volumes. If a screwdriver needs to be replaced, the system automatically detects it. There is no longer a need to manually access machine data on site, and unauthorized interventions are immediately flagged. From an economic standpoint, this leads to maximum service life utilization and helps prevent downtime due to wear. At the same time, we’re setting a new standard in transparent documentation and KPI calculation — because the data is always available and can be analyzed at any time.

The new quality class

The IPM solution for recording process data from axle assembly provides Mercedes-Benz Group at the Mercedes-Benz plant in Hamburg with all the important information for quality planning and assurance. The software is a strategic component of a product life cycle file. The Mercedes-Benz plant in Hamburg manufactures axles, steering columns and system elements for passenger cars in state-of-the-art production areas. One focus is on the production of rear and front axles for the C-Class, smart and other model series. More than one million rear and front axles are produced here on the plant site every year. In order to make comprehensive basic data from the production process available via the IT network for the purposes of quality assurance, the Hamburg plant and the Stuttgart-Untertürkheim plant both installed the IPM software from CSP GmbH & Co. KG from Großköllnbach. IPM (the acronym stands for “Integrated Process Data Management”) collects process data from any connected plant and presents it in meaningful reports, statistics and graphics.

Conversion of existing systems

Previously, a file-based system was used to record process data. This was far from being able to meet all the requirements of production and quality management at Mercedes-Benz. Instead of screwdriving sequences, the system could only provide the measured end values for statistical evaluation. Moreover, the screwdriving curves had to be read out from the internal memory at the plant, which involved increased personnel effort. IPM was introduced at the same time as a new production line for the Mercedes 204 series, the current C-Class. The new system for rear axle assembly was installed both in Hamburg and Untertürkheim. As the project initiator, the Untertürkheim plant selected the IPM solution from CSP. Several Mercedes-Benz locations had already had many years of very good experience with the software house and its QS-Torque solution, which is used to plan, perform and evaluate quality inspections in series production. IPM now convinced with advantages such as simpler and faster process monitoring, automated notifications when threshold values are exceeded and clear, daily updated web reports.

IPM provides basic data for quality planning and assurance

“IPM enables preventive quality assurance. The tool provides all the basic data required from the process for quality planning. The software was therefore strategically anchored in Mercedes-Benz’s IT concept and is part of our internal solution PLA, the product life cycle file. Here, IPM covers the so-called ‘small control loop’,” explains Stephan Ivanauskas, who is responsible for the administration of the quality systems at the Mercedes-Benz plant in Hamburg. From a quality perspective in particular, it is necessary to precisely document all manufacturing steps throughout the entire process. Mercedes-Benz must ensure that only flawless parts are used in its vehicles, and not just for reasons of product liability. These values from production are initially stored in IPM for a period of six months, after which the data are archived long-term in the product life cycle files (= PLA). Overall, the process data is stored for several decades. The IPM was introduced in 2006, with the project team proceeding successively. It started with the system for the rear axle 204 (current C-Class). Stephan Ivanauskas describes the procedure as an example for the Hamburg plant: “Our approach was to gradually link IPM to the systems in the axle assembly area. Axle assembly is a sensitive production area with the highest quality requirements, particularly due to the many different bolted connections, because the vehicles are subjected to considerable continuous stress in everyday use. Here, the quality simply has to be perfect.

Rollout to the entire plant

During the pilot, the overall project was initialized, interfaces defined and the necessary databases installed. After IPM reliably provided the data of the first plants, IPM was rolled out to the entire plant following the piloting. Many existing plants were thus gradually connected to the process data management solution. While the previously used solution only processed file-based information, IPM is supplied directly with data and values from the process via TCP/IP. The IPM telegram format is already supported by numerous well-known device manufacturers. Today, it is primarily the plant engineers who work with IPM and the evaluations from the production process. The screw curve analysis also provides important basic data for continuous process control and quality planning. These values are then processed further in a statistics program at Mercedes-Benz. A total of around 140 employees at the Hamburg plant can access IPM via the network. In addition to the plant engineers, the foremen, quality assurance staff, process planners and development staff are among the users who benefit from the data and reports provided by IPM in their daily work.

Strategic decision

“Quality assurance is the highest asset for Mercedes-Benz as a brand in the premium segment. Therefore, the introduction of IPM was primarily based on strategic considerations. Our aim is to use the database that is now available to identify potential weaknesses in the process and eliminate them at an early stage,” says Stephan Göb, Head of Quality Management. Even though IPM was not primarily used to reduce costs, the efficiency of the solution can be seen in everyday work in a whole series of advantages: For example, a great deal of time is saved in axle assembly, which previously had to be spent compiling data. By networking the production systems with the software for process data management, for example, there is no longer any need for cumbersome data transfer. Whereas very frequent product audits and spot checks with regard to product quality had to be carried out before, these are now required at shorter intervals. In addition, much more meaningful evaluations can now be compiled because screw curves and thus numerous individual values from the process are now also available. Mercedes-Benz has already connected a total of more than 14 systems to IPM at its Hamburg plant. The simple but continuous and automated process data management system reliably ensures the very high quality standards that Mercedes-Benz demands of its products in axle assembly. Accordingly, the evaluation of physical measurement data is also a prerequisite for new plants. Their connection to IPM is required by definition in the specifications and the required interfaces are described precisely. Thus, new plants are connected to IPM without exception in the sense of the strategic product life cycle file and supply the desired production data to the software.

“Competent and reliable”

“CSP has been a project partner that has proven to be very fast, competent and reliable. Currently, we are very well taken care of with a support contract,” says Stephan Invan-auskas about the cooperation with CSP.

Profile of the Mercedes-Benz plant in Hamburg

The Mercedes-Benz plant in Hamburg was founded in 1935 as Vidal & Sohn Tempowerk GmbH and today, together with the plants in Berlin-Marienfelde, Stuttgart-Untertürkheim and Kölleda, is part of the Powertrain Mercedes-Benz Cars Production Division of Mercedes-Benz Group. Axles, steering columns and system elements such as pedal systems, gearshifts and parking brakes are manufactured on the 326,650 square meter site. The Mercedes-Benz plant in Hamburg is a lightweight construction center for components. The further development of technologies as well as the entire process chain from concept investigation to series production takes place here in state-of-the-art production areas. Around 2,600 employees work at the site.