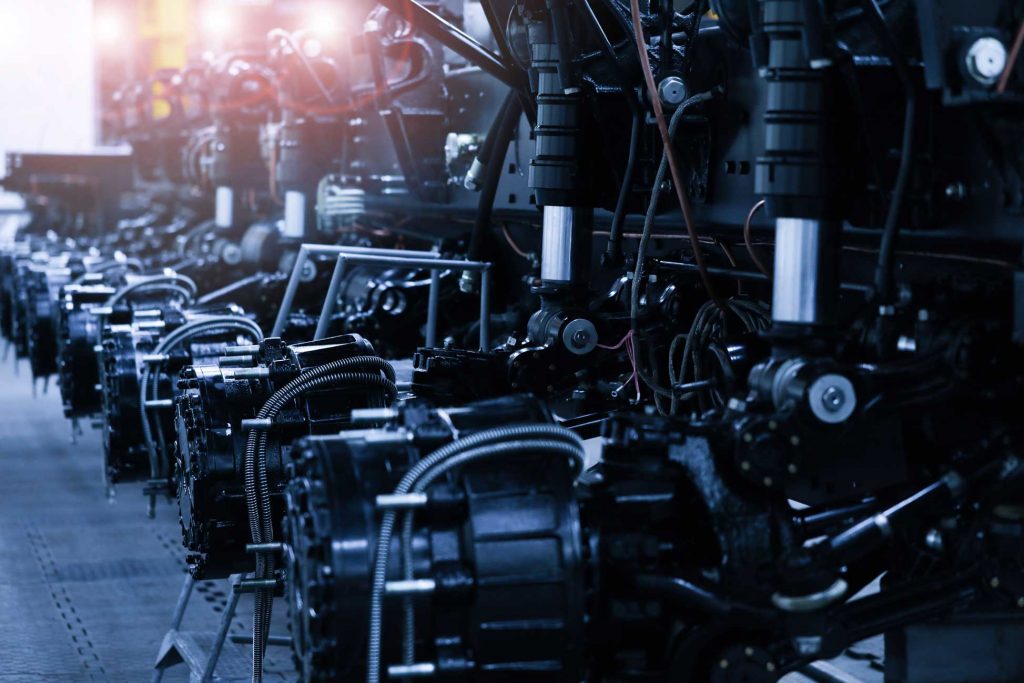

Seamless integration with leading manufacturers

Integrated process data management IPM for maximum production quality

Stop production errors before they happen

The more complex your production, the higher the risk of quality problems and rejects. IPM records all relevant process data in real time, analyzes it intelligently and alerts you to deviations at an early stage – ensuring product quality and reducing costs.

✓ Real-time monitoring of all production processes

✓ Automatic alerts for quality deviations

✓ Sustainable reduction of scrap and rework

100

95

30

Atlas Copco⚬

Desoutter⚬

Bosch Rexroth⚬

HKS⚬

KUKA⚬

Sarissa⚬

Stanley⚬

Siemens⚬

SCS⚬

viele mehr⚬

Atlas Copco⚬

Desoutter⚬

Bosch Rexroth⚬

HKS⚬

KUKA⚬

Sarissa⚬

Stanley⚬

Siemens⚬

SCS⚬

viele mehr⚬

Atlas Copco⚬

Desoutter⚬

Bosch Rexroth⚬

HKS⚬

KUKA⚬

Sarissa⚬

Stanley⚬

Siemens⚬

SCS⚬

viele mehr⚬

Incomplete process data – high risk

If you do not document consistently, you risk quality, product liability – and your market position.

Legal Liability

Without complete process documentation, your company can be held liable for quality defects.Expensive Recalls

In an emergency, a lack of traceability forces you to recall entire batches – even though only individual parts would be affected.Certification Issues

Audits can fail if process data is not available in full – ISO 9001, IATF 16949 & Co. are at risk.Reputation Damage

Defects caused by undetected process deviations jeopardize your customers’ trust in the long term.

Ensure quality – avoid risks

IPM documents processes seamlessly, detects errors at an early stage and ensures legal security and sustainable efficiency.

Product Liability & Audit Security

Seamless, audit-proof recording of all process data – for maximum traceability and legal security.Seamless System Integration

Works with your existing MES, ERP and IT systems, regardless of manufacturer.Automated Data Analysis

Detects process risks at an early stage – before errors occur or rejects are produced.Real-Time Detection Instead of Reaction

Process deviations are reported immediately – rework and recalls are avoided.GDPR & Compliance Ready

Meets all data protection, quality and documentation requirements (e.g. FDA, ISO, IATF).

CUSTOMER SINCE 1995

BMW Group

20% less downtime – with end-to-end process monitoring

BMW was looking for a solution to reduce production downtime and high reject rates in complex production lines. The goal: early fault detection and end-to-end traceability.

20

less downtime

30

less scrap & rework

100

process traceability

- Unplanned downtime due to undetected process deviations

- High reject and rework rates

- Complex traceability in the event of complaints

Result with IPM:

- 20% less downtime thanks to real-time data

- Scrap and rework reduced by up to 30%

- Complete traceability of all relevant process steps

- Significantly reduced quality costs through early intervention

Data acquisition

IPM records all quality-relevant process data – regardless of manufacturer and system.

Documentation

Every step is documented seamlessly, in compliance with standards and legislation – completely audit-proof.

Evaluation

From real-time monitoring to detailed, historical evaluations: IPM makes your quality data visible and usable.

Monitoring

IPM alerts you immediately in the event of discrepancies – automatically by e-mail, dashboard or interface.

CUSTOMER SINCE 2019

Lion Smart

100% documented production – zero risk in battery manufacturing

Lion Smart was faced with the challenge of fully documenting sensitive battery cell production data in order to meet product liability and OEM requirements.

100

documented manufacturing

- Incomplete documentation of individual process data

- High manual effort to ensure traceability

- Risk of recalls in the absence of reliable evidence

Result with IPM:

- 100% documented manufacturing processes per cell

- Automated data analysis and seamless archiving

- Product liability fulfilled in an audit-proof manner

- Real-time optimization of process parameters for better quality

ALL ADVANTAGES AT A GLANCE

Early error detection

IPM detects process deviations in real time before faulty products occur – this noticeably reduces rejects and rework.

Time and cost savings

Less rework, lower error rate, more efficient processes – IPM measurably reduces process costs.

Manufacturer-independent integration

IPM seamlessly integrates a wide variety of tools, machines and systems – even in heterogeneous production environments.

Audit-proof traceability

IPM documents seamlessly and in compliance with the law – ideal for complaints, audits and to safeguard product liability.

Process and quality control

IPM replaces manual inspection processes with automated, digital monitoring – relieving employees and reducing sources of error.

Central quality data at the push of a button

All quality-relevant process data is consistently recorded, evaluated and archived – for maximum transparency and well-founded decisions.

CUSTOMER STORIES

Leading companies trust IPM

Increase product quality throughout the entire production process

The more complex your production, the greater the risk of errors. IPM records, analyzes and monitors your process data in real time – so that you can detect errors early on and prevent rejects.

FAQ

Is IPM compatible with my tools?

Yes, IPM is manufacturer-independent and supports common market systems.

How long does the implementation take?

In many cases, integration is possible within a few days—thanks to preconfigured interfaces.

Can IPM be customized to fit my processes?

Absolutely. IPM is modular and tailored precisely to your manufacturing environment.

Which processes are supported?

- (Flow-hole) screwing

- Press-fitting

- Filling

- Bolting

- Leak testing

- Inline measurement

- Resistance spot welding, friction element welding

- (Stamping) riveting

- Distance measurement

- Flange measurement

- Laser soldering

- Cold and hot gluing / adhesive monitoring

- Flanging

- Temperature monitoring

- Camber / caster adjustment

- Steering alignment

- Roll hemming

- Ultrasonic sensing

- Polish pattern / chisel test (destructive testing)

- Clinching

- Pressing

- BestFit

- and much more

Which manufacturers can be connected?

- AMT Alfing Montagetechnik GmbH

- Apex Tool Group GmbH & Co. OHG

- Asentics GmbH & Co. KG

- Atlas Copco Holding GmbH

- Aventics GmbH

- Bosch Rexroth AG

- Carl Zeiss AG

- CLAAS KGaA mbH

- DOGA Steuerungstechnik GmbH

- Desoutter GmbH

- Eisenmann intec GmbH & Co. KG

- EJOT Holding GmbH & Co. KG

- ERTL Automation GmbH & Co. KG

- EST Elektronische Schraub- + Steuerungs-Technologie GmbH & Co. KG

- FEV Europe GmbH

- Fraunhofer-Institut für Keramische Technologie und Systeme

- GE Measurement

- Gebr. Schmid GmbH

- George Renault

- GWK Norbert Gerlach GmbH und Co. KG

- Harms & Wende GmbH & Co. KG

- Heldele GmbH

- Hochrainer GmbH

- HBM – Hottinger Baldwin Messtechnik GmbH

- HKS Prozesstechnik GmbH

- iBG Robotronic GmbH

- InfraTec GmbH

- Ingersoll Rand GmbH

- Inkodatec automation GmbH

- in-situ GmbH

- JW FROEHLICH Maschinenfabrik GmbH

- Kistler Instrumente GmbH

- Klingel GmbH

- KUKA AG

- Marposs GmbH

- Matuschek Meßtechnik GmbH

- Perceptron

- QUISS AG

- PROMESS Montage und Prüfsysteme GmbH

- Saltus Industrial Technique GmbH

- Sarissa GmbH

- SCA Schucker GmbH & Co. KG

- SCS Concept Group

- Siemens AG

- SIHI Anlagentechnik GmbH

- Stanley GmbH

- Tucker GmbH

- Tox Pressotechnik GmbH & Co. KG

- TruckCam

- USK Karl Utz Sondermaschinen GmbH

- Vision Tools Bildanalyse Systeme GmbH

- Weber Schraubautomaten GmbH

- Wilhelm Böllhoff GmbH & Co. KG

- ZELTWANGER Holding GmbH

- IPM is manufacturer-independent and can be expanded to support any hardware manufacturers.

What connection options are available?

- IPM telegram format

- RFC 1006

- Universal telegram format

- XML

- QS-Stat

- CSV files

- OpenProtocol PF4000

- OPC UA

- and many more