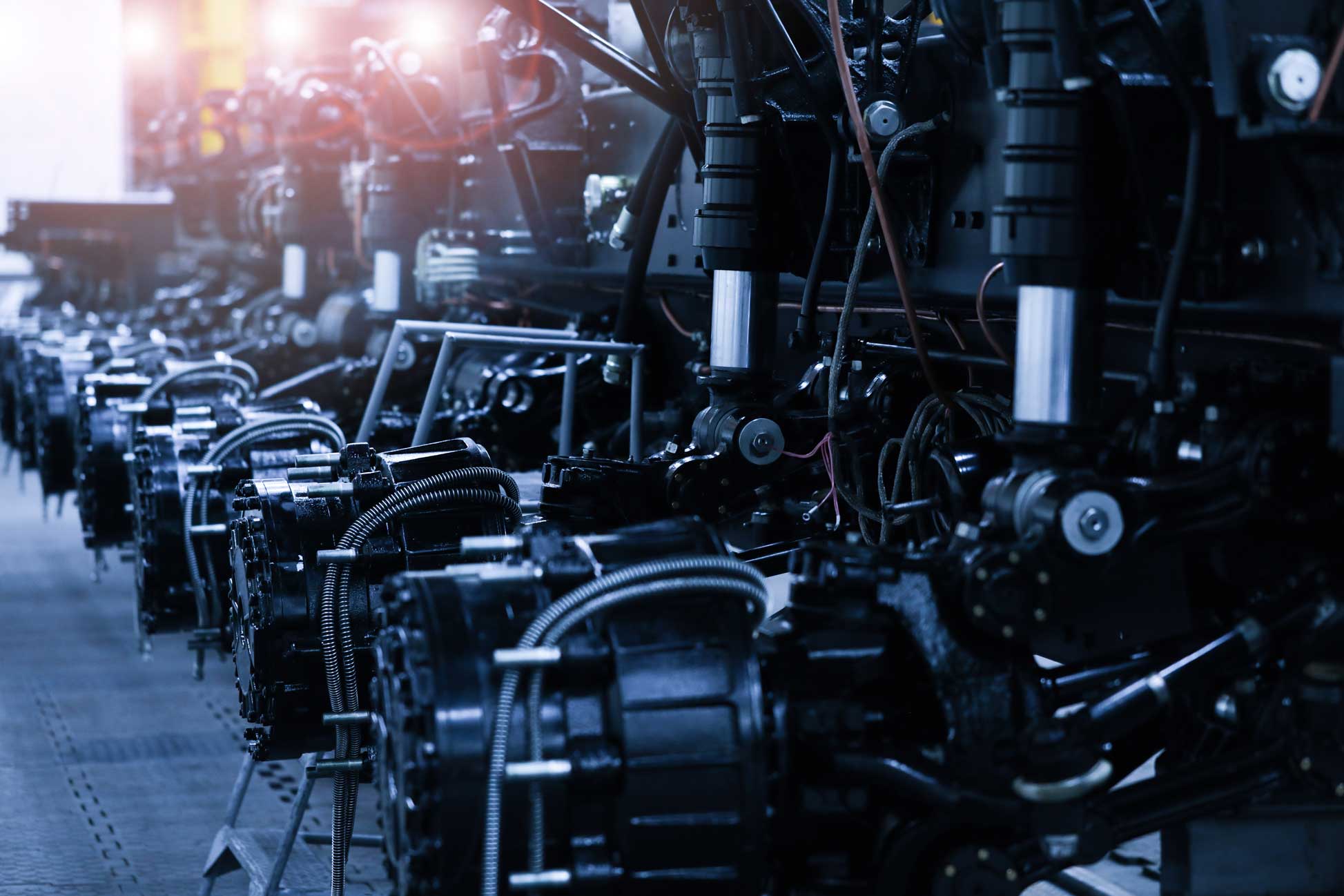

Over 30,000 bolts are tightened every production day at the axle production facility of MAN Truck & Bus AG in Munich. To consistently achieve this output at the highest quality, machines must be kept in top condition at all times through regular maintenance and care. Since our goal is to continuously optimize automation and production, even long-established practices must be re-evaluated.

That’s why we no longer rely on air-operated impact wrenches in axle assembly, but predominantly on electronic screwdrivers with integrated monitoring functions. Only with this technology can we ensure the precision of bolted joints and the safety of our vehicles, even under extreme stress.

Production structure in focus

Maintenance is no longer just about repairing defective machines and systems — it’s also about collecting innovative knowledge on optimal production structures. This includes automatically securing critical production data and constantly monitoring equipment.

In 2012, we laid the foundation for a new system: screw cycle recording. The basis for networking all screwdrivers was implemented for 80 screwdriving systems. Now it is possible to store production data — such as torque and angle of rotation — on a central server and retrieve it online.

In cooperation with the planning department of software company CSP and the electrical maintenance team, the existing IPM archiving system was adapted so that it automatically triggers a maintenance order after every 100,000 to 1 million screwdriving cycles.

Maintenance at the optimal time

Maintenance can now be performed condition-based and at exactly the right time — something that was previously difficult due to fluctuating production volumes. If a screwdriver needs to be replaced, the system automatically detects it. There is no longer a need to manually access machine data on site, and unauthorized interventions are immediately flagged.

From an economic standpoint, this leads to maximum service life utilization and helps prevent downtime due to wear. At the same time, we’re setting a new standard in transparent documentation and KPI calculation — because the data is always available and can be analyzed at any time.